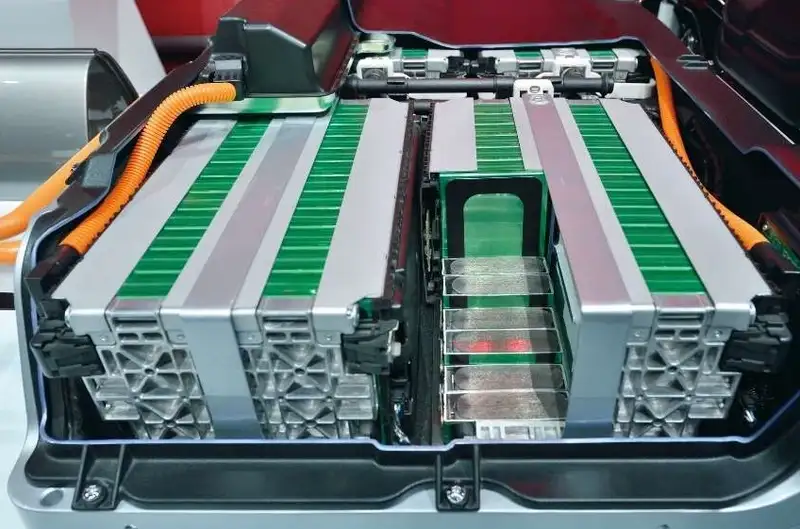

Mining for electric car batteries is extracting raw materials from the earth. These materials are then used to create the raw material needed to turn into lithium-ion batteries.

Two main ways electric car batteries are mined are underground and open pit mining. Mining is done by underground or open-pit techniques, depending on which type of ore you’re looking for. The more common technique involves digging deep holes into the earth to extract a specific quality of ore.

Mining is a difficult process, often requiring human labor and large machinery. It can be an arduous task that requires a lot of energy.

What are the benefits of mining for electric car batteries?

Mining for electric car batteries is more popular, largely due to their environmental benefits. They also need less maintenance and cost less to operate than a traditional combustion engine car.

Mining plays an important role in the manufacturing process, helps to maintain ecosystems, and helps to decrease pollution. The benefits of mining include a good ROI.

Here are the benefits of mining for electric car batteries :

- Mining electric car batteries help to reduce pollution.

These cars are a great way to reduce CO2 and other harmful pollutants. They improve energy efficiency and are great for the long-term health of our planet.

- Mining for electric car batteries also brings in revenue that can be used to fund environmental protection initiatives.

The mines also provide a home to many endangered animals and help to preserve the habitat

- Mining electric car batteries help maintain a healthy ecosystem.

Mining electronic and electric car batteries are vital in the production process, which in turn helps sustain the health of an ecosystem.- The mines also help maintain a healthy balance between vegetation, water sources, and wildlife.- Mining also provides jobs for the community

- Mining for electric car batteries keeps the demand high.

The demand for electronic and electric car batteries is maintained because of their widespread use in many industries, such as aviation, transportation, and construction.

- Mining electric car batteries help to ensure product quality.

Miners ensure that the product they are mining is safe by adhering to strict regulations that maintain quality and standards.

- Mining electric car batteries help to ensure a sustainable future.

Miners do not contribute to the depletion of mineral reserves and must adhere to strict regulations that help ensure the long-term sustainability of resources.

What is the process of mining for electric car batteries?

Electric cars are battery-powered, so they need electric car batteries. Electric car batteries can be mined in two ways: open-pit and underground mining.

Open-pit mines tend to be the most expensive type but also the most popular due to their low production costs.

The process of mining electric car batteries is complex, but several steps take place before a battery can be made.

- The first step is to find out where the deposit is located, which can be done by either on-site exploration or remote exploration through geophysical surveys.

- The second step involves drilling exploratory holes into the site to uncover the deposit and determine its size. Once this has been done, the extraction begins by drilling a shaft into the deposit and loading it up with explosives.

This explosion will break up the rock so the drill can be lowered into the deposit to dig out the raw materials. Once the raw materials are loaded into a truck, they will be taken back to the nearest factory for processing.

- The third step entails separating each rock layer so all the minerals can be extracted. Once complete, a battery manufacturing process begins by mixing each mineral and using an electrolysis chemical process.

- The fourth step is when a dead battery is resold or donated to companies for use in electric cars.

What are some of the biggest companies in this industry?

Mining electric car batteries is a big business, and many companies are involved in this industry.

According to the International Energy Agency, the electric car battery market is expected to grow quickly, with an estimated $27 billion in revenue by 2023.

The biggest companies in mining for electric car batteries include Tesla, BMW, Daimler, Volkswagen, and Nissan.

Read Also: 5 Benefits of Mining In Colorado | Best Mining, Exploitation, and Jobs

What are some of the most common types of mining for electric car batteries?

Graphite, lithium, and cobalt oxide are the main components of an electric car battery’s cathode. These sturdy ingredients are used in industrial and consumer electronic batteries worldwide.

Today’s electric car batteries are made from recycled materials such as lithium, nickel, iron, or copper.

There are three main types of mining for electric car batteries.

- The first is the lithium-ion battery with a cathode made from graphite, lithium, and cobalt oxide.

- The second type is the nickel-cadmium battery with a cathode made from manganese oxide, nickel, and cadmium oxide.

- Lastly, the lead-acid battery uses sulphuric acid as its electrolyte.

How long does it take to mine an electric car battery?

Electric cars are more popular than ever, and this is because of their Eco-friendly nature. However, the downside of these cars is that they require a lot of electricity to run, which is why many people still rely on fossil fuels.

Mining for an electric car battery can take up to a few hours, depending on the size and shape of the battery. Once you find it, you need to remove it from its casing and install it in your car.

How much energy does it take to mine electric car batteries?

Mining for electric car batteries uses a lot of energy, but it’s not just how much it consumes that is significant in this process. It’s also the amount of energy required to make them as well.

Battery cases are made in a process that requires high temperatures. The case comes together at over 1,000 degrees Celsius.

Solar power isn’t the most common option for mining electric car batteries. The costs aren’t too great, but they aren’t accessible to everyone.

How many electric cars are currently on the market?

The number of electric cars on the market has increased significantly over the past few years. This is mainly due to the introduction of more affordable models and a shift towards cleaner energy.

As of September 2018, there were 362,000 electric cars in North America and Europe. By 2022, this number is expected to reach 7 million.

How much do mining companies charge to extract the minerals from an area?

Mining companies charge different rates depending on the region. For example, in the United States, mining companies charge $5.00 per ton to extract gold or copper.

How can mining electric car batteries help the environment?

Mining for electric car batteries is an Eco-friendly method of disposing of e-waste.

Electric cars, which are becoming more common, seem to have started a trend that will increase the demand for lithium-ion batteries shortly. Mining electric car batteries can decrease the company’s carbon emissions while providing valuable materials.

How is the mining process for electric car batteries different from other forms of mining?

Mining for electric car batteries is often different from other forms of mining. It is also known as the “mine” because it requires digging deep into the ground to reach the battery cells.

Electric car batteries are mined using a specialized machine with two arms that dig into the ground and pull out a battery. This machine uses electricity to break down rocks and dirt into tiny particles, which are then sent through a tube into an airtight chamber where they can be processed and turned into aluminum, copper, or cobalt.